TPE (polycarbonate elastomer) is various from typical rubber products (such as EPDM and silicone) because it does not call for vulcanization. What is tpe material?TPE is a thermoplastic material that can be processed by heating and melting, while vulcanization is a normal procedure for thermosetting rubber (such as EPDM). The following is the handling modern technology of TPE and its distinction from vulcanization:

TPE handling innovation

TPE processing mainly depends on thermoplastic molding technology, and typical procedures include:

1. Shot Molding

Refine description: Heat tpe sealing strips to a liquified state, infuse them right into the mold and cool them to create.

Benefits:

1)High production efficiency, suitable for mass production.

2)Products with intricate forms can be made.

Applications:

This way can be also used into making TPE sealing strips, takes care of, gaskets, ect

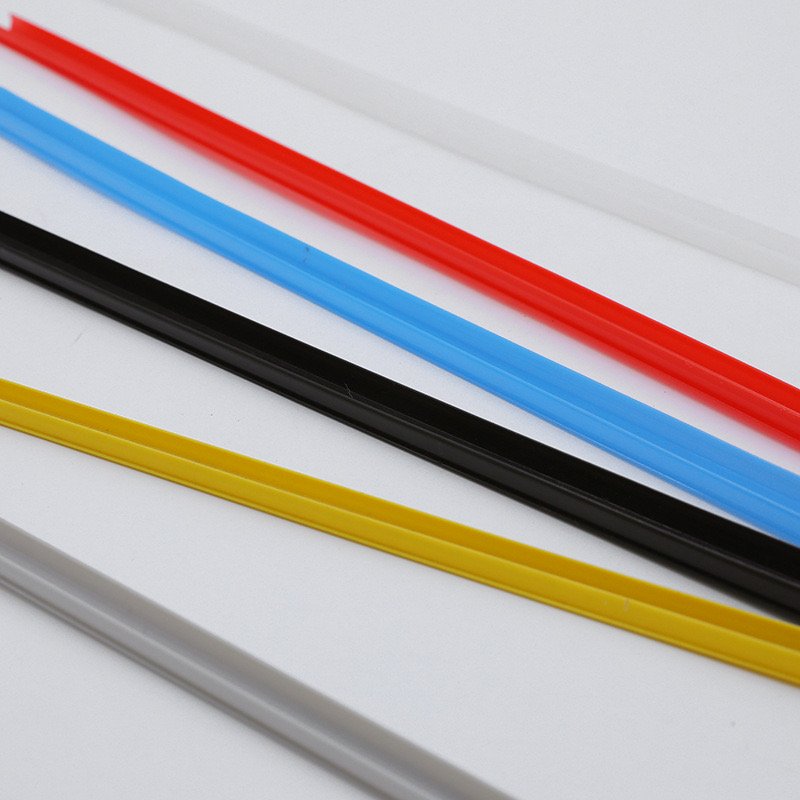

2. Extrusion molding (Extrusion).

Refine summary: After heating TPE fragments, they are built via the extruder head to continually generate lengthy strips or tubular products.

Advantages:.Appropriate for the manufacturing of constant items such as rubber strips, securing strips, pipes, etc;Low cost and high performance.

Application: This way can be used to making TPE sealers,also for the Windows and door seals, auto seals, cable television sheaths, and so on

3. Blow Molding.

Refine Description: Molten TPE is impact built right into hollow items.

Advantages:.Suitable for the manufacturing of hollow or thin-walled items.

Application: Pipes, air bags, etc,manufacturers less use this way to produce sealers.

4. Calendering.

Refine Summary: Melt TPE and press it right into sheets or movies through a calender.

Benefits:Suitable for the manufacturing of slim sheets or film products.

Application: Water-proof rolls, gaskets, etc

5. Overmolding.

Process Description: Infuse TPE onto the surface area of other materials (such as PP, ABDOMINAL) to create composite items.

Advantages:.Enhance the soft qualities and capability of the product.

Application: Device deals with, electronic equipment housings, and so on.

The distinction between TPE and epdm

| Attributes | TPE (thermoplastic elastomer) | Vulcanized rubber (such as EPDM seal) |

| Processing modern technology | Heating and melting molding (no need for vulcanization) | Vulcanization is called for (heating + vulcanizing agent cross-linking) |

| Recyclability | Repeatable handling, eco-friendly | Non-recyclable, thermosetting material |

| Production performance | High (rapid air conditioning molding) | Low (lengthy vulcanization time). |

| Handling temperature level | 150– 230 ° C | 160– 200 ° C (vulcanization temperature level). |

| Mold cost | Low | High |

| Application adaptability | Suitable for intricate shapes and little batch personalization | Suitable for massive standardized production |

Trick parameters of TPE processing

1.Handling temperature level:.Generally 150– 230 ° C, the particular temperature depends on the kind and solidity of TPE.

2.Mold temperature level:.

Generally 20– 60 ° C, too high mold and mildew temperature might cause item deformation.

3.Injection pressure:.

Changed according to item shape and size, usually 50– 150 MPa.

4.Cooling time:.

TPE cools down swiftly, normally 10– 30 secs, depending on the thickness of the item.

Advantages of TPE processing.

- No requirement for vulcanization: conserve time and energy, high manufacturing efficiency.

- Recyclable: scraps and waste can be refined consistently to decrease prices.

- Adaptable layout: appropriate for complex shapes and multifunctional items.

- Environmental management: does not have vulcanizers and follow environmental requirements such as RoHS and REACH.

- Can be well applied to the production process of door and window strips

Summary.

TPE’s handling technology is mostly based on polycarbonate molding, including injection molding, extrusion, blow molding, and so on, without vulcanization, and is effective, environmentally friendly and flexible. If you need to understand more concerning the technical details of TPE or you need TPE sealing strips, please call us for expert assistance!