With the quick growth of the door, home window and drape wall sector over the last few years, the door and home windowstrip seal sector has actually likewise brought in an increasing number of attention frome the market.

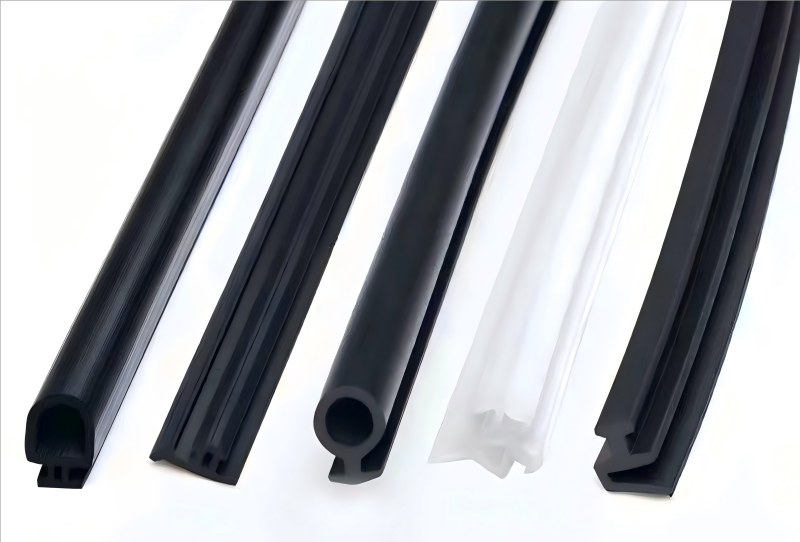

Presently, door and window seal strips (windows and door rubber seal strips) are mainly made use of in plastic steel doors and windows, aluminum alloy doors and windows, wood doors and windows and various other building attractive doors and windows. The plastic steel windows and door seal strips on the market are usually extruded from PVC, customized PVC, rubber door seal strip, elastomer seal strips (consisting of TPV, TPE material, TPR, SEBS), silicone and various other materials.

So, what is the function of windows and door seal strips?

It is comprehended that the seal strip plays an essential function in waterproofing, securing and power conserving in plastic steel doors and windows, damaged bridge aluminum windows and doors and wood windows and doors, sound insulation, dustproof, antifreeze and warmth. It must have solid tensile toughness, good elasticity, and fairly good temperature resistance and aging resistance. In order to guarantee the attachment of the strip and the profile, the cross-sectional structural dimensions of the strip must match the plastic steel door and window profile.

Sealing strips are typically utilized for casement windows and doors, hanging windows, and hinged doors and home windows. The main features are dustproof, insect-proof, waterproof, soundproof, sealing, and so on.

Nevertheless, as a result of the influence of many factors such as the current technical level; the door and window sealing strips on the market are likewise blended. In many cases, as a result of incorrect choice of sealing strips, door and window business have engineering quality troubles and rework, which not just brings economic losses to door and window drape wall firms, but likewise creates damages to the business’s track rocord.

So, what issues might occur with general windows and door sealing strips presently? Via multi-party investigations, it is located that there are normally the complying with symptoms:

- Poor-quality windows and door sealing strips have a variety of unsafe substances (such as: soluble cadmium, antimony, lead and other heavy metal health hazards), and the volatilization of these soluble harmful compounds will seriously harm human health.

- Poor-quality door seals and window seals may have poor securing or split glue at the edges, causing water leakage crashes.

- After being exposed to sunshine or heat, the sealing strip comes to be sticky and complies with the home window and glass. In some cases “oil seepage” takes place, which pollutes the doors and home windows and influences the sealing function and appearance of the doors and home windows.

- The securing seal strips for windows and doors will end up being difficult and weak right after use, hence losing their initial elasticity and securing feature; causing problems such as water leakage and ventilation prior to the project is approved.

The above is an introduction to the types of door sealers and window sealers, their uses, and some problems that may exist. Thanks for reading.