——Good material of door seals and window seals would will have a longer service life.

Many people pay attention to the quality when buying doors and windows, but they often ignore the window seals and door seals.

You should know that although the sealing strip is inconspicuous, it is also very important. It has a great impact on the use of doors and windows!

The features of door and window seals:

Rubber seal plays an important role in waterproofing, sealing and energy saving in plastic steel doors and windows, thermally broken aluminum window and doors , wooden doors and windows, as well as sound insulation, dust prevention, antifreeze and warmth preservation. It must have strong tensile strength, good elasticity, and relatively good temperature resistance and aging resistance.

In order to ensure the tightness of the weatherstipping and the profile, the cross-sectional structural dimensions of the rubber strip must match the plastic-steel door and window profile.

Sealing strips are generally used on casement windows, hanging windows, and folding windows. The main functions are dustproof, insect-proof, waterproof, soundproof, sealing, etc.

Material of door weatherstrip and window seals:

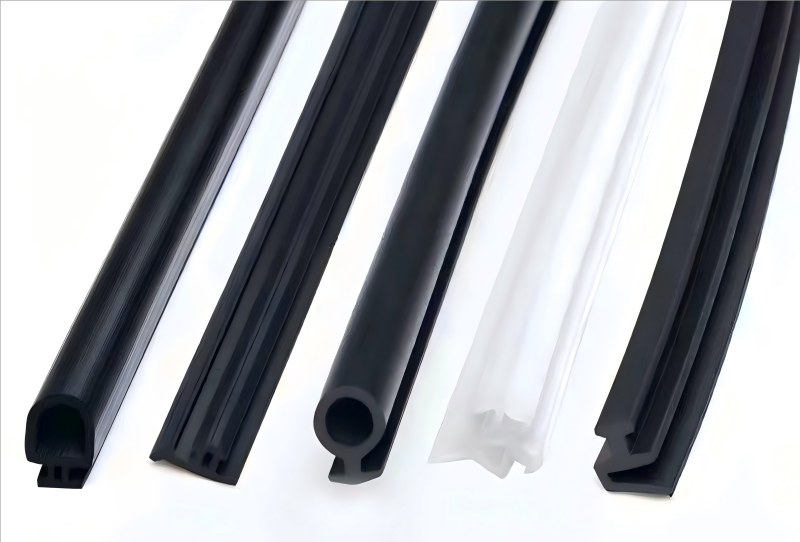

Window seals and door seals on the market are generally extruded from pu,epdm,gasket,rubber,epdm rubber,thermoplastic polyurethane ,pvc,modified PVC,elastomeric sealing strips (including TPV, TPE, TPR, SEBS), silicone and other materials.

Types of door sealers and window sealers:

Door weather stipping can be divided into three categories according to their different uses: door leaf and door frame sealing strips, wool strips, and sealing glass shower door (pvc strips).

Door leaf cover sealing strips are mainly used for sealing between door panels and door frames, wool strips are mainly used for sealing between door frames and door leaves, and glass sealing strips are mainly used for sealing between glass and door leaves and frames.

Notes on installation of window and door sealers:

1. Rubber sealing strip

It cannot be pulled too tight, and the cutting length should be 20-30mm longer than the assembly length. When installing, it should be inlaid in place, with a straight surface, close contact with the glass and the glass notch, so that the force around the glass is even. The rubber strip should be cut off at the corner with an inclined surface, and glue should be injected at the cut to make it firmly bonded.

2. When using sealant to fill the seams and fix the glass, you should first squeeze the glass with a rubber strip or rubber block to leave a gap for injection. The injection depth should be no less than 5mm. Before the glue solidifies, the glass should be kept free from vibration.

3. The installation location of the Weather Stripping for sliding door and windows is generally on the window (door) sash, around the frame sash or on the sealing bridge (wind block) to enhance the seal between the frame and the sash.

4. The specifications of the door weather stripping are important factors affecting the sliding door with windows and the watertight performance, and are also important factors affecting the opening and closing force of doors and windows. If the door weather stippings are too large or the vertical wool is too high, it will not only be difficult to assemble, but also increase the resistance to the movement of doors and windows, especially the initial resistance when opening and the final resistance when closing.

5. If the specification is too small or the height of the vertical weather stippings is not enough, it is easy to fall out of the groove, which greatly reduces the sealing performance of the doors and windows. The weather stippings needs to be siliconized. The appearance of the qualified weather strippings is flat, the bottom plate and vertical wool are smooth and without bending, and there are no pits on the bottom plate, which meets the requirements of 0.2mm.

How to choose door seal strip and window seals?

1. Smell

Use your nose to smell whether there is any peculiar smell. Normal PVC material will only have a little bit of alcohol smell, which is almost negligible.

2. Pull with your hands

Take a sealing strip and tear it at its thinnest part. The greater the force, the higher the glue content. This means that the overall performance of this sealing strip is very good and you can consider purchasing it.

Hold the door strips in their hands, and have two people hold one end each, and pull it in both directions like pulling a rope. First, see if it can be broken, and then see if it can rebound to its original length. The better the elasticity of the sealing strip, it means that after the sealing strip is installed, it will not be deformed due to long-term closing pressure of the door.

3. Scrape with fingernails

Sealing strips made of poor materials have low glue content and their surface is easily scratched white. After this type of sealing strip is installed on the door, it will be “broken” if it is hit by hard objects or slightly scratched, which is very unsightly.

4. Observe the surface

Some cheaper sealer strips have a lot of fillers, so the surface is not very bright. Those cheap ones with dull appearance are not advisable. Then look at the cross-section joint of the sealing strip to see if the brightness is close to the surface color of the sealer stripd. If it is close, it means that the sealer strip material does not contain much filler and it can be purchased.

5. High temperature test

Wrap the door strips or window strips as tightly as possible around the profile, place it under high temperature for a period of time (place it on the roof or in a sunny place), and observe whether the surface of the profile and the contact surface of the sealing strip are stained or discolored, whether the surface of the seal strip is dusty and yellow (if there is oil on the surface of the sealing strip, it is easy to absorb dust) and oil leakage, and whether it gets your hands dirty. Seal strips made of high-quality materials have smooth surfaces and are dust-proof, oil-resistant, and high-temperature resistant. They will not turn yellow or leak oil or get your hands dirty under high temperature.

6. Weigh the seal strips of the same material

The same amount of sealing strips with good material will be light in weight. Adding talcum powder , heavy calcium, etc. to the sealing strips to increase the weight of the product will be much heavier than adding light calcium carbonate . In addition, the sealing strips are priced by weight in their sales. Therefore, when choosing sealing strips, it is necessary to weigh the sealing strips of the same material and model.