Let me discuss to you what the self-adhesive sensation of rubber is.

Self-adhesion is a bonding sensation, that is, the same unvulcanized rubber is bonded and the phenomenon of assimilation occurs after a specific time period. In the rubber rolling stage of the rubber sealing strip manufacturer, two pieces of rubber are quickly stuck. This is the outcome of the shared diffusion and penetration of the rubber macromolecules on both bonding surface areas through molecular thermal motion. The fastness of this bonding is particularly high, reaching numerous kilos per centimeter, which means that there is attachment on the bonded surface. This characteristic is one-of-a-kind to unvulcanized rubber, the supposed self-adhesiveness.

Self-adhesiveness has both advantages and negative aspects for rubber handling. The benefit is that it provides bond for the bonding and molding of numerous items to guarantee that the bonding components are firm. The disadvantage is that self-adhesion is not required in some process web links. In order to prevent bond, an isolation agent is likewise called for.

The mechanism of self-adhesion is that when two layers of unvulcanized rubber with the exact same parts enter into contact with each other, mutual diffusion in between particles happens at the interface through infiltration. After a period of time, the user interface gradually vanishes and both components are incorporated into one. Since the unvulcanized rubber macromolecules are slender and soft, when they relocate, a specific segment develops a space because of flexing, and the sectors of nearby particles squeeze in, forming a rugged state. When the results of the movement of numerous molecular sections at the interface collect to a particular stage, self-adhesion is created.

Interpretation of rubber self-adhesion sensation

The self-adhesion sensation refers to the sensation that the interface of the exact same unvulcanized rubber product gradually merges right into one after a particular time period after contact. This characteristic is special to unvulcanized rubber, and the rubber loses its self-adhesion after vulcanization.

Mechanism of self-adhesion phenomenon

Molecular diffusion and penetration

When two pieces of unvulcanized rubber come into call, the rubber macromolecules (long-chain polymers) on the surface diffuse because of thermal motion, and the molecular sections permeate and ensnare with each other, developing a framework comparable to “jagged teeth”.In time, the user interface slowly goes away and eventually merges right into a whole.

Dynamic characteristics of molecular sectors

The molecular chains of unvulcanized rubber are slender and flexible. During movement, neighborhood sectors will certainly form spaces, and adjacent molecular segments will certainly take the opportunity to squeeze in, forming a physical cross-linked network.

Adhesion strength

The bond created by self-adhesion is exceptionally high, getting to a number of kilograms per centimeter, which is close to the stamina of rubber itself.

Advantages and disadvantages of self-adhesion

Benefits and drawbacks

Attachment molding: Offers bonding force for rubber products (such as sealing strips) to ensure that the parts are securely bound. Refine disturbance: Some procedures (such as piling and transport) require to prevent attachment, and extra seclusion agents (such as talcum powder) are required.

Simplified process: Smooth bonding of numerous layers of products can be attained without adhesive. Product waste: Improper procedure may cause product bond and scrap.

Boosted efficiency: The stamina of the bonding part is close to the body to prevent tension concentration. Storage space requirements: Unvulcanized rubber requires to be sealed and kept away from light to avoid self-adhesion failing.

Practical application of self-adhesion

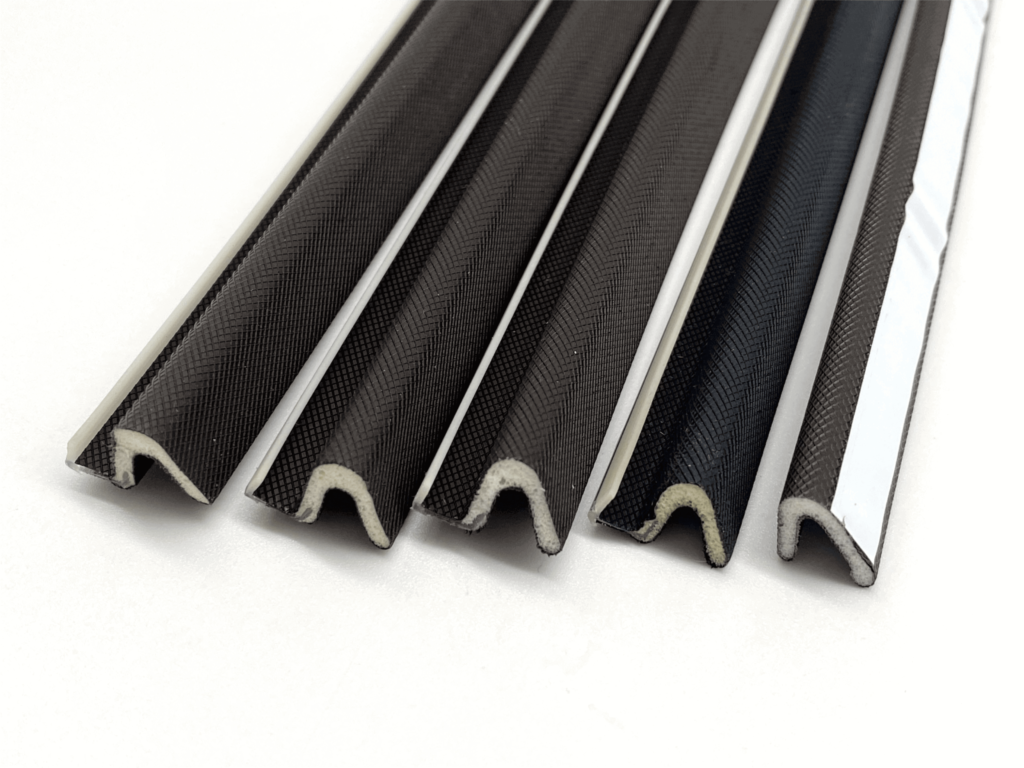

Rubber sealing strip manufacturing:In the rubber rolling process, self-adhesion is utilized to bond multiple layers of rubber to form a sealing strip of uniform thickness.

Bonding result is optimized by regulating car parking time and temperature level.

Tire molding

Unvulcanized rubber cable layers are adhered by self-adhesion, lowering the use of glue and enhancing manufacturing efficiency.

Anti-adhesion procedures

In processes that do not require self-adhesion, usage seclusion representatives (such as talcum powder, silicone oil) or isolation films to avoid unintentional attachment of rubber.

Summary

Self-adhesion is the core residential property of unvulcanized rubber, which originates from the dynamic diffusion and infiltration of molecular chains.

Logical use of self-adhesion can simplify the procedure and improve item top quality, yet anti-adhesion measures should be taken in details procedures.