Structural material comparison guide

▎EPDM (ethylene propylene diene monomer)

Features: UV/ozone/climate triple protection

Application scenarios:

✔️ Car door and window seals (all-weather aging resistance)

✔️ Outdoor equipment seals (anti-rain and sun exposure)

✔️ Photovoltaic module frame seals (stable at -50℃~150℃)

▎Silicone

Features: -60℃~230℃ ultra-wide temperature range, flexible as before

Advanced applications:

🔥 Aircraft engine high temperature gaskets

❄️ Cold chain logistics vehicle seals

⚡ High-voltage insulation seals (dielectric strength 15kV/mm)

▎Neoprene

Chemical protection shield:

▶️ Resistant to engine oil/hydraulic oil/weak acid and alkali (PH3~11)

▶️ Industrial model:

✔️ Chemical plant reactor seals

✔️ Automobile gearbox gaskets

✔️ Offshore platform anti-corrosion seal

▎Nitrile rubber (NBR)

Guardian of fuel system:

▶️ Gasoline permeability resistance is 300% higher than natural rubber

▶️ Must-use scenarios:

⛽ Fuel pipe seal

🔧 Diesel engine cylinder gasket

⚙️ Hydraulic system O-ring

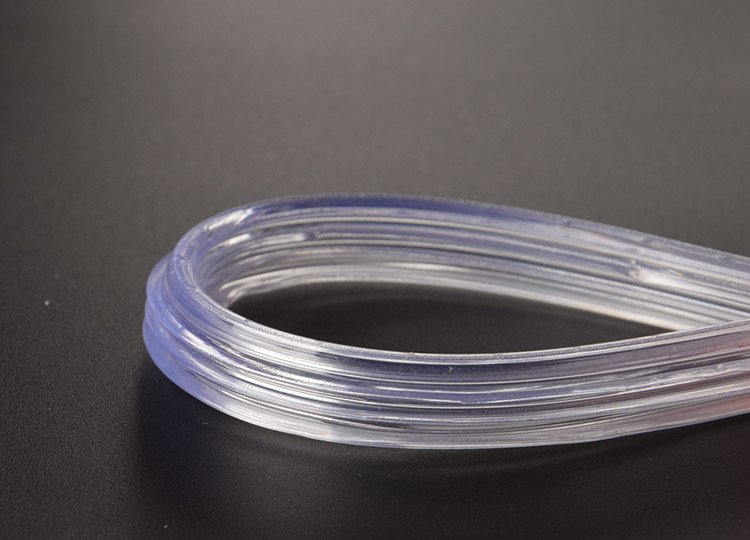

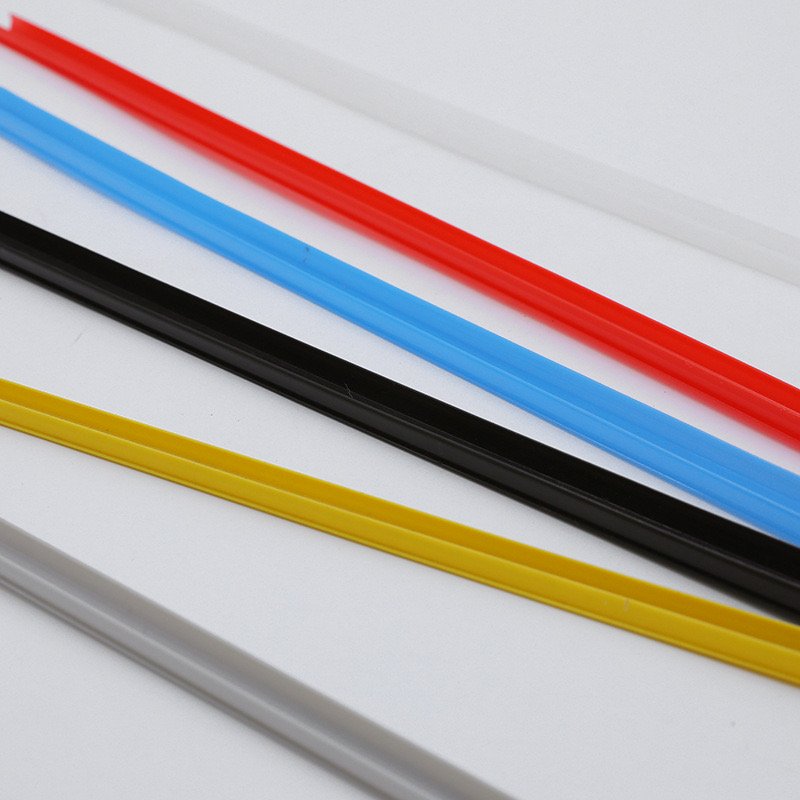

▎PVC (polyvinyl chloride)

Economical solution:

▶️ Door and window seal cost reduced by 40%

▶️ Upgraded version:

✔️ Plasticized (flexibility ↑30%)

✔️ Flame retardant (oxygen index ≥28)

✔️ Antistatic (surface resistance 10^8Ω)

Material selection decision matrix

| Working condition challenges | Preferred materials | Key indicators |

| Long-term outdoor exposure | EPDM sealing strips | UV resistance Class 8 |

| 150℃ high temperature environment | Silicon seals | Thermal weight loss rate <5% (230℃/72h) |

| Gasoline immersion | Nitrile rubber (NBR) | Volume expansion rate <15% |

| Acid and alkali corrosion | Chloroprene rubber/fluororubber | Acid and alkali concentration gradient table |

| Low-cost door and window seals | PVC modified material | Shore hardness 75A±5 |

Summary

Analyze sealing technology from the perspective of material science, master the weather resistance mechanism of EPDM molecular chain and the thermal stability principle of Si-O bond of silicone, so that material selection can be upgraded from empirical judgment to data-based decision-making, truly realizing “one material to seal the world”.