The installation and use door sealers and to obtain closed securing in between accounts and glass, and in between sashes and frameworks. Protecting strips play the role of handling glass, buffering resonance and blocking water and air blood flow in utilizing doors and windows. The thermal insulation and airtightness of windows and doors have a substantial effect on power preservation and intake reduction of frameworks. The warmth loss of doors and windows with poor protecting is 5-6 times the heat loss of walls. The energy-saving efficiency of doors, home windows and curtain wall surfaces represent regarding 37-40% of structure energy preservation. Therefore, the strip is a practical accessory that can not be disregarded in the energy-saving standard of doors and windows, and its performance and service life should attract our attention.

Today, due to various factors, the strip market is combined. There are still lots of programmers and windows and door companies that make use of sealer strips that do not meet the standards of “Securing Strips for Structure Doors and Windows” for low cost. Along with the reality that the strip manufacturers need to further improve their focus to the energy-saving door and window sector, they need to additionally boost their identification skills for rubber door seal strips in numerous web links such as development, guidance and door and window production. When choosing strip seals, take note of the adhering to elements of judgment to promote the general renovation of the securing quality of windows and doors.

Material selection

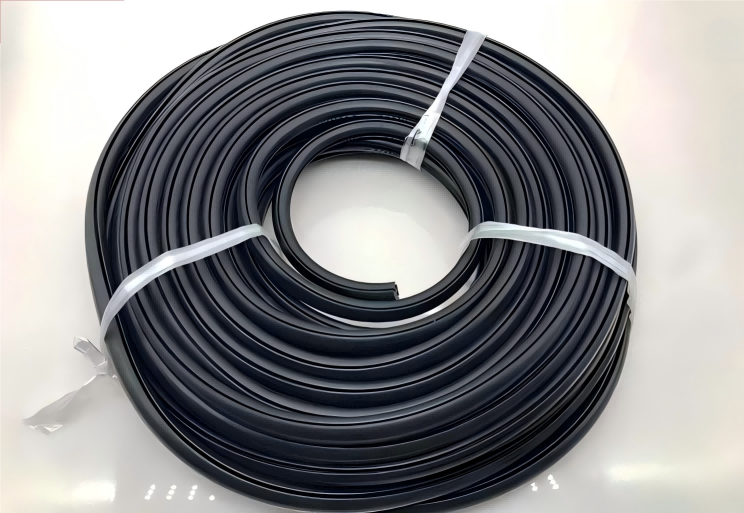

The performence and life of door seal strips and window sealers depend first on the selection of products. From the category of chemical structure materials in my country, the major materials utilized for black window sealers and window sealing strips are split into two categories: polycarbonate elastomer sealing strips and vulcanized rubber sealing strips.

1.Thermoplastic elastomer sealing strips (SJT).

① PVC resin cylinder single blended changed product.

The strips made by modifying PVC material with a polymer modifier (typically utilizing cross-linked nitrile rubber or rubber-type chlorinated polyethylene) are typically called combined polyvinyl chloride elastomer sealing strips or modified polyvinyl chloride securing strips. This product has been added with a polymer modifier, which boosts the durability and high and low temperature resistance of the sealing strip. It has high strength and good aging resistance. The fundamental physical buildings can fulfill the GB/T12002 or JG/T187 standards. It is moderately valued and is presently commonly utilized in the manufacture of structure windows and door sealing strips.

Some companies utilize waste materials of varying high quality and complicated components to produce door strips, and do not add modifiers when mixing, and add too much fillers, which come to be high-filled PVC sealing strips. This sort of strip has inadequate strength, reduced flexibility, and is simple to damage. Some manufacturers also include aromatic oil or hefty oil from oil refining deposits to replace plasticizers, that makes the securing strip items not just poignant, however additionally deform and reduce in a short period of time, and also diminish, making the doors and home windows shed their sealing feature, so this kind of strip must be restricted.

② EPDM/PP cross-linked dynamically vulcanized thermoplastic elastomer product (TPV).

This is a new product that has been standardized abroad and has sector criteria in China. It is utilized in structure doors and windows in the house and abroad. The performance of this TPV material is equivalent to that of vulcanized EPDM rubber. As a result of its excellent processability, low specific gravity, high home window price, and no heavy metals and halogens, it is a new energy-saving and eco-friendly material with high sensible worth. High-quality realty jobs with a price of more than 4,000 yuan/M2 have started to utilize it.

③ High-polymerization resin cross-linked blended customized elastomer silicone strip seal(TPE).

The greatest feature is that it does not call for a vulcanization process, yet makes use of a thermoplastic plastic molding method for processing, which can significantly reduce the molding cycle, and the waste can be reused and reused, which is conducive to saving money and power. It is an extremely encouraging material and can be made use of as a substitute for vulcanized rubber. The customized polyvinyl chloride strip seals has good resistance to permanent contortion of compression, and is taken into consideration by the National Building Association to be able to change EPDM as a strip gasket and weatherproof strip for windows and doors. Its performance coincides as TPV, yet the raw product formula utilized is various. The present sales price is slightly less than TPV. For customers, it is a good and cheap item that enhances the quality of windows and doors without increasing costs. It has a very high market promo worth and has come to be the preferred material for medium and high-end windows and door producers and export products.

2.Vulcanized rubber sealing strips are primarily ethylene propylene diene monomer rubber (EPDM).

The gasket strip made of this product have superb aging resistance and appropriate for windows and door securing. They were as soon as the preferred product for securing at home and abroad. Nonetheless, its vulcanization and shaping call for a vulcanization assembly line to finish, which has high production prices.

The cost of EPDM original rubber is reasonably high, whcih makes the cost of high-end EPDM securing strips high. The lower-priced items on the marketplace are loaded with a huge amount of calcium powder, waste materials, etc, and have low quality.

EPDM items have a huge specific gravity, reduced window rate, include heavy metals, and include nitrosamines (health hazards). Many nations have explicitly outlawed their usage indoors. Furthermore, the item can not be recycled and is not conducive to environmental protection. For the existing worldwide promotion of the idea of green enviornmental defense, it will certainly be slowly removed by the market.

View test report.

Whatever material the upvc window sealers and door sealing strips are made of, it must have sufficient tensile strength, good elasticity and hardness, and its physical properties must meet the various indicators of GB12002-89 standard or JG/T187 -2006 standard. When purchasing, you should check the manufacturer’s test report and product certificate, and sign a quality assurance agreement with the manufacturer. The service life of PVC modified sealing strips that meet the standards can reach 15-20 years, and the service life of thermoplastic EPDM (TPV) sealing strips can reach more than 30 years.

Experimental performance test.

- Observe whether the surface of the rubber strip is flat, free of impurities, bubbles, and serrations, and feels delicate and soft to the touch. Highly filled soft PVC or EPDM sealing strips have poor elasticity, rough surface, and large deformation.

- They will not break when stretched moderately by hand, and can recover quickly after being bent and released. Highly filled soft PVC sealing strips have poor strength, crack when folded, and break when pulled.

- Use your nose to smell whether there is any aromatic odor. Some PVC sealing strips not only use waste materials of varing quality, but also add excessive fillers and low molecular weight aromatic olefin oils or complex refining oil residue heavy oils as plasticizer substitutes in the formula. This product has a strong odor when it is just shipped out of the factory. As time goes by, the component evaporates more, and the sealing strip quickly hardens and becomes brittle, causing the strip to shrink, loosen, fall off, and easily crack and age, losing its sealing function. The migration of aromatic olefin oil or heavy oil will also cause the profile to turn yellow.

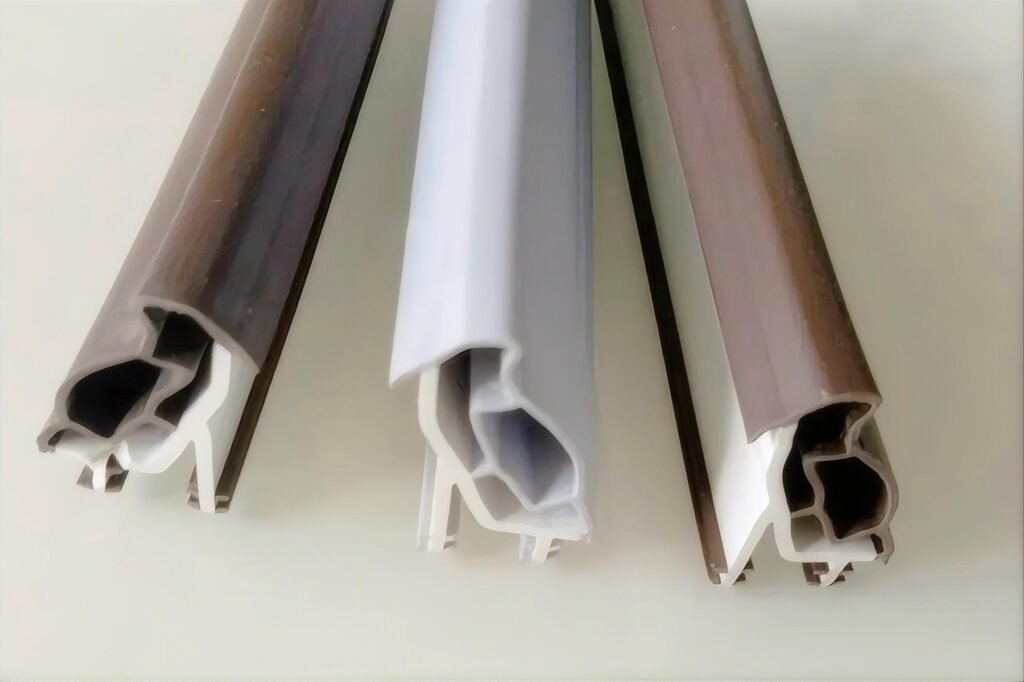

- Practical inspection: embed the strip between the profile and the glass, and check the rationality of the cross-sectional shape of the strip and the suitability of the size. It is not difficult to press the strip in, and the greater the force of pulling out the glass, the better. If conditions permit, you can also find a professional third-party testing agency to conduct watertight and airtight tests.

In summary, the quality of the adhesive rubber strips can be intuitively identified from the appearance, strength, odor, and combustion of the sealing strip:.

- The surface of inferior polyvinyl chloride (PVC) sealing strips is rough, with large deformation and poor strength, and it breaks when pulled. There is a pungent aromatic olefin smell when you smell it. After the combustion is self-extinguished, the wire drawing is very short due to more fillers and less resin.

- The surface of high-quality modified polyvinyl chloride (PVC) sealing strips is delicate, bright, strong, elastic, and odorless. When burning, the flame is yellow, the root is green, there is a chlorine smell, and the wire drawing is long after burning and self-extinguishing.

- EPDM seal has good strength, elasticity, small deformation, bright surface, and high specific gravity (about 1.5). When burning, the root of the flame is blue, smokeless, and the residue is non-sticky. It can not be drawn after burning.

- Thermoplastic elastomer TPV/TPE rubber for sealing have better performance than EPDM seal strips, can float on the water surface (specific gravity 0.90-0.95), have excellent resilience and tensile properties, and come in a variety of colors.

Improve the quality awareness of below door seals and window seal sealants.

From the analysis of the mid-range door and window market, the cost of rubber sealing only accounts for 0.1-0.5% of doors and windows. For the entire construction project, its cost is even negligible, but strips of rubber’s role can not be underestimated. We have encountered a company that provided doors and windows for high-end villas with serious quality problems. The owner found that rainwater had penetrated the doors and windows before moving in. After investigation, it was found that it was caused by the shrinkage of the rubber strip seals. As a result, all the products were reworked and replaced with Kamo products. The company saved a small amount of money but caused huge economic and reputation losses.

Therefore, we should start frome various links such as development companies, supervision units, door and window companies, and strip seal production companies to improve the understanding of door and window functions and related seals, correctly handle the relationship between price and quality, and leave a reasonable price space for the production and use of standard sealing strips.

Secondly, the relevant supervision and door and window companies should insist on standard review for the purchase and use of window sill sealers and. All low-priced and low-quality sealing strips that do not meet the standards shall not be used to regulate the building accessories market. Relevant standards such as “Sealing Strips for Plastic Doors and Windows” (GB/T12002 -1989) and “Sealing Strips for Building Doors and Windows” (JG/T187 -2006).

Third, best sealer for windows and door sealers production companies should continuously improve their sense of social responsibility, eliminate inferior sealing strips, actively promote process and technological innovation, establish they’re own brands, not participate in low-price competition, and promote the continous improvement of the industry level.