Let’s explore the secrets of the production process of epdm sealing.

With the advancement of science and technology and economic growth, the demand for new materials in many industries is increasing. Sealing materials are key components to ensure the normal operation of equipment and improve service life, and are particularly important in the construction, automobile, machinery and other industries. In order to meet the demand for efficient and reliable sealing materials in these fields, the research and development of sealing strips is particularly critical.

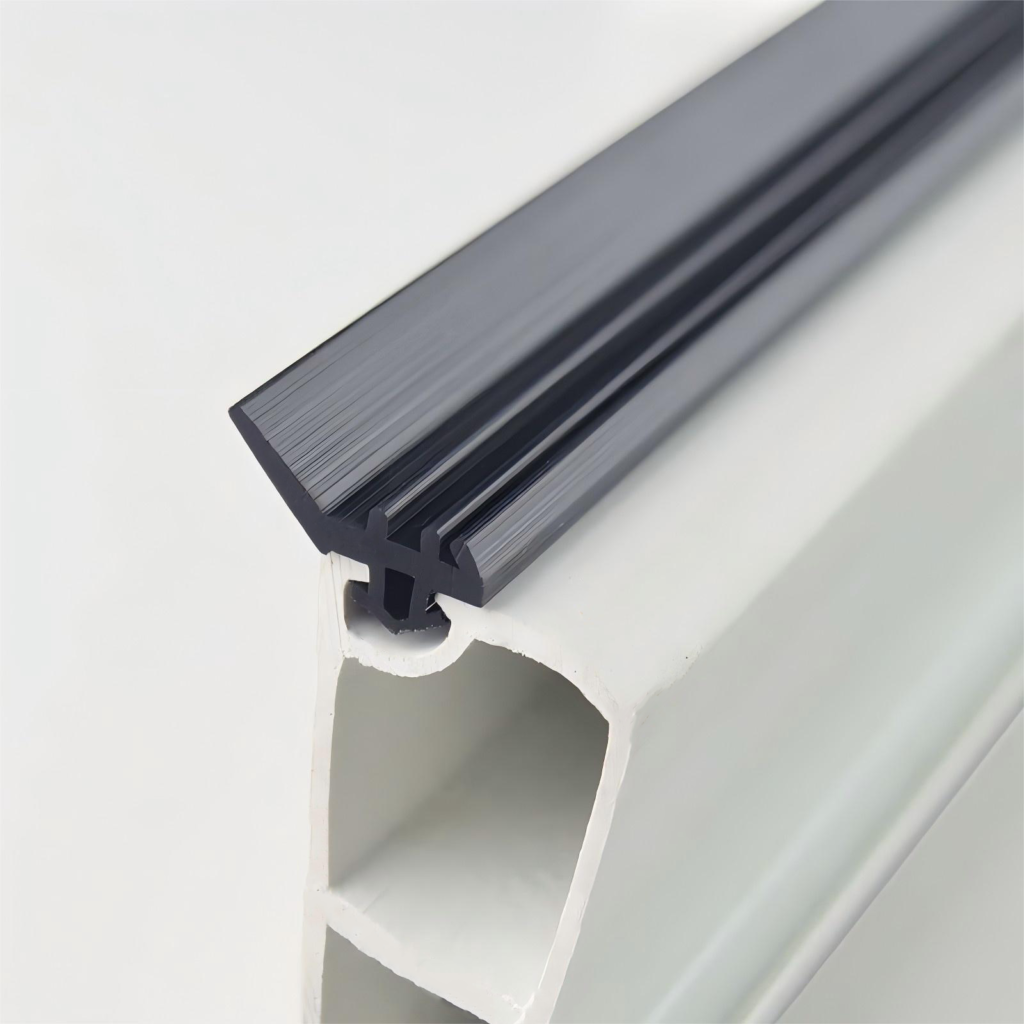

One of the core technologies for producing rubber door seal strip,which is made ofethylene propylene diene, is comprehensive vulcanization technology. Through this technology,epdm rubber seal can be vulcanized at one time during the production process, thereby ensuring that the window epdm seal strips have excellent sealing performance and bonding strength. The key to this process is to perform length truncation and vulcanization steps at the same time to achieve efficient production and optimize product performance.

Among the many sealing strip materials, rubber sealing strips have become the first choice due to their excellent elasticity, heat resistance and chemical resistance. In particular, EPDM rubber seal which is made of ethylene propylene diene rubber epdm, have become the leader among rubber sealing materials due to their excellent comprehensive performance. In order to further explain the technical characteristics of EPDM rubber door sealing strips, this article will focus on the core technologies used in zhis.

The other technology for producing epdm window seal is continuous vulcanization technology, which strengthens the production process of sealing strips and improves the overall quality of sealing strips. In the continuous vulcanization process, a variety of vulcanization methods can be used, including salt bath vulcanization, hot air vulcanization, etc. This requires operators to have high professional skills to ensure that the quality of EPDM rubber meets the highest standards.

Another is microwave vulcanization technology, which is an efficient and environmentally friendly vulcanization method. It can not only effectively vulcanize epdm sealer, but also ensure the performance and appearance quality of the sealing strip. High temperature vulcanization technology is also one of them. This technology requires rapid high temperature during vulcanization and keeps the surface of rubber door seal strip flat to avoid affecting the performance and appearance of the sealing strips.

It is worth noting that these advanced vulcanization technologies not only improve the performance of the product, but also meet the requirements of environmental protection and sustainable development. By precisely controlling the vulcanization process, it is possible to minimize the impact on the environment while improving production efficiency and product quality.

In short, the vulcanization technology of EPDM rubber sealing strips is the key to its excellent performance. EPDM rubber sealing strips adopt advanced technologies such as integrated vulcanization, continuous vulcanization, and microwave vulcanization, which can not only improve the performance of the product, but also adapt to the ever-changing market demands and provide high-quality sealing solutions for the construction, automobile, machinery and other industries.